Automotive Wiring Harness Testing Market - Drivers and Forecasts by Technavio

time2017/12/07

Automotive Wiring Harness Testing Market - Drivers and Forecasts by Technavio

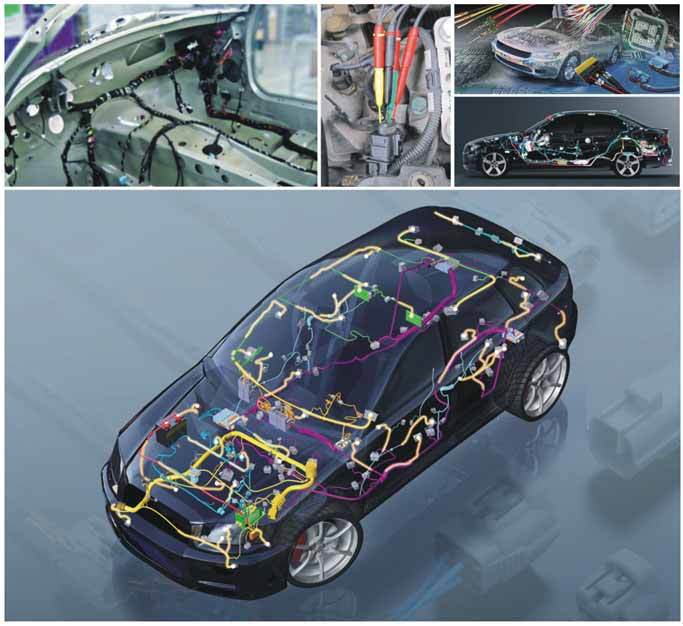

The research study covers the present scenario and growth prospects of the global automotive wiring harness testing market for 2017-2021. Wiring harness testing is a method to determine the continuity of the wiring harness by checking for short or open circuits and to check the capacity of components such as relays, diodes, and capacitors.

The market would have a rapid growth due to an increase in the demand for EVs. EVs use more wiring harness than conventional vehicles. This will have a massive impact on the global automotive wiring harness testing market. The demand for EVs is increasing across several regions. The Chinese government has considered banning gasoline cars to control air pollution. India has planned to move to 100% EVs by 2030. Volkswagen has planned to launch 30 new EV models by 2025 to counter the increasing demand for EV.

This report is available at a USD 1,000 discount for a limited time only: View market snapshot before purchasing

Buy 1 Technavio report and get the second for 50% off. Buy 2 Technavio reports and get the third for free.

Technavio analysts highlight the following three factors that are contributing to the growth of the global automotive wiring harness testing market:

Increasing demand for high-speed connectivity solutions

Technological advancement in wiring harness testing

Expanding EV sector driving the demand for wiring harness testing

Looking for more information on this market? Request a free sample report

Technavio’s sample reports are free of charge and contain multiple sections of the report including the market size and forecast, drivers, challenges, trends, and more.

Increasing demand for high-speed connectivity solutions

Earlier, vehicles consisted of more mechanical components as compared with electronic components. In recent years, the electronic content per vehicle has increased to more than 50% in some vehicles. This is due to an increased adoption of advanced safety features and powertrain electrification.

Raj Gaurav Singh, a lead automotive services research analyst at Technavio, says, “New and upcoming vehicles have many electronic components and sensors, which led to the development of more complex safety protocol. All of these modules are interconnected and communicate with each other through the ECU. As a result, traditional wiring harnesses are unable to support the bandwidth requirements owing to high-speed data transmission.”

Technological advancement in wiring harness testing

During the 1990s, an automotive wiring harness tester could test about 1,000 test point in 60 seconds. In 2016, it can test about 1,000 test point in 3 seconds. This is due to the technological development achieved by using electronic switches. A simple low voltage wiring harness tester is used for testing only the continuity of the wiring by checking for any open or short circuit. Another wiring harness testing examines the components through a high-voltage tester.

“Improvement in technology has made testing simpler, where the components can be tested efficiently using a low-voltage tester. Dynalab's NX series, which are low-voltage testers, can be used for continuity testing and other testing such as active testing on relays in a wiring harness. The relay is fixed into the output module accessory and tester, which serves as the mating fixture,” adds Raj.

Expanding EV sector driving the demand for wiring harness testing

Safety features, such as DAS, and regulatory mandates stipulating the installation of OBD2 to reduce greenhouse gas emissions cover 50% of the vehicle's cost. However, in EVs, the electronic content can go as high as 70% owing to electrification of terrain and advanced safety features.

Wiring harnesses used in EVs have also evolved along with the new generation EVs. Earlier, EVs used harnesses that could handle voltage up to 12V. As a result, the shielding requirement is less as compared with current EVs that can handle voltage up to 48V. The increased voltage will not only require better shielding of wiring harnesses to reduce electromagnetic interference, but also safety systems in place to protect the occupants in case of accidents.